Build Your Dream Ride with Mia

What is BTDC? Before Top Dead Center Explained

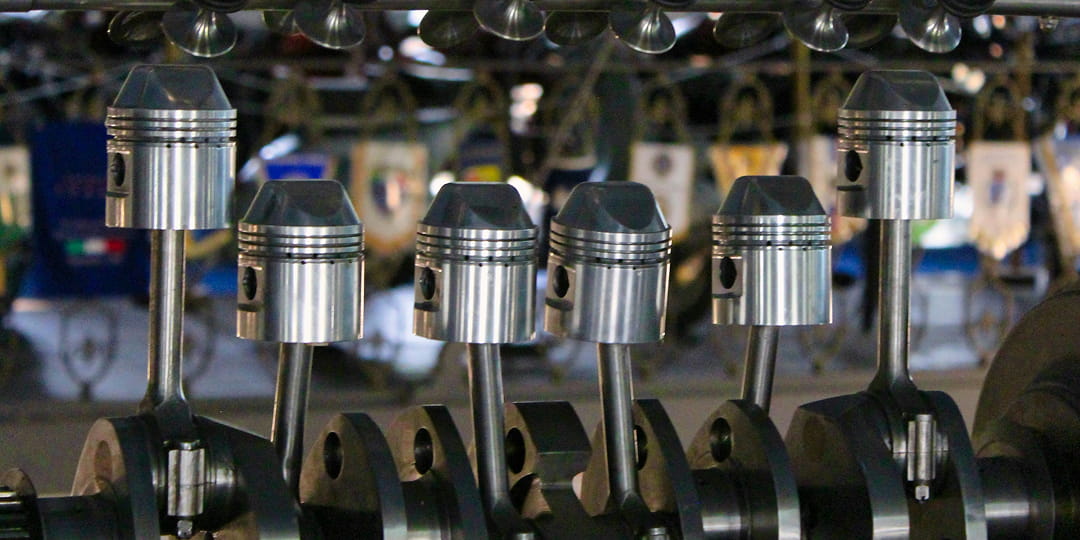

BTDC (Before Top Dead Center) refers to the crankshaft position before the piston reaches its highest point in the cylinder. It is measured in degrees and is used to time ignition or valve events. Ignition often occurs BTDC to ensure complete combustion and optimal engine performance.

Top Dead Center (TDC) is that exact moment when the piston stops rising and starts falling. But if you wait until TDC to light the fire, you’ve already missed your chance for maximum power. By the time combustion pressure builds, your piston is already heading down, wasting potential energy.

When someone says their engine runs “10 degrees BTDC,” the spark fires when the crankshaft is 10 degrees before the piston hits TDC. Since a complete engine cycle involves 720 degrees of crankshaft rotation, those few degrees make a massive difference in efficiency.

Why timing occurs before TDC

Combustion takes time, typically 15 to 20 milliseconds. During those milliseconds, your crankshaft keeps spinning. If you sparked at TDC, peak pressure would occur too late to do useful work.

The goal is reaching peak pressure around 14 to 16 degrees ATDC. This gives maximum leverage when the piston begins its power stroke. At idle, your crankshaft might spin at 800 RPM. At redline, it could turn 7,000 RPM or more. The combustion process takes roughly the same time regardless, so higher speeds need more advance to maintain optimal pressure timing.

BTDC vs ATDC: Key differences

BTDC and ATDC represent opposite sides of the piston’s journey. BTDC measurements occur during the compression stroke as the piston approaches TDC. ATDC happens during the power stroke as the piston moves away from TDC. Most ignition timing discussions focus on BTDC because that’s when spark occurs, but ATDC matters for understanding combustion dynamics.

The fundamental difference lies in their purposes. BTDC timing controls when combustion starts, while ATDC events show combustion results. You set BTDC to achieve specific ATDC pressure peaks. Valve timing also uses these references, with intake valves often opening BTDC and exhaust valves closing ATDC, creating valve overlap that helps cylinder scavenging.

Some diagnostic scenarios require ATDC measurements. Diesel injection timing on certain engines specifies ATDC values. Analyzing cylinder pressure traces means understanding both BTDC ignition points and ATDC pressure peaks. Racing engines might even use ATDC ignition under specific conditions, though this is rare and requires sophisticated engine management.

Why ignition happens before TDC

The physics of combustion demands early ignition. Flame front propagation has physical limits. Even under ideal conditions, it takes time for the flame kernel at the spark plug to grow into a full combustion event.

The spark creates a small flame kernel that grows, consuming nearby fuel molecules and heating adjacent mixture. As temperature rises, chemical reactions accelerate, creating a propagating flame front. This process can’t be rushed, no matter how strong your ignition.

You want peak pressure when the connecting rod angle provides maximum mechanical advantage. Since pressure buildup takes time, starting combustion at the right moment BTDC becomes critical for extracting maximum work from each combustion event.

How to measure BTDC

Accurate measurement separates successful builders from those relying on guesswork. The process requires attention to detail and proper tools.

Required tools and equipment

A timing light tops the essential list. Quality matters since cheap lights give inconsistent readings. You’ll need basic hand tools for adjustment, a vacuum gauge for advance diagnosis, and ideally a piston stop for finding true TDC. A degree wheel becomes invaluable for cam timing or building performance engines.

Finding top dead center

The piston stop method provides precision. Thread it into the spark plug hole and slowly rotate the engine until the piston contacts the stop. Mark the balancer position. Rotate backward until it hits again. Mark this position too. True TDC lies halfway between marks.

Using timing marks on the harmonic balancer

Factory marks on the balancer and timing cover show BTDC degrees. The balancer mark aligns with numbered degree marks on the timing pointer. Zero represents TDC, with numbers increasing in the advance direction. Remember that outer ring slippage on older balancers can throw readings off.

Verifying BTDC with a timing light

Connect the inductive pickup to number one plug wire. With engine warm and vacuum advance disconnected, aim the light at timing marks. The strobe freezes spinning marks. Note where the balancer mark aligns. Increase RPM slowly while watching advance. Total timing typically occurs by 3,000 RPM in stock engines. MotorMia’s platform can help you research advance curves based on proven combinations.

How to set and adjust BTDC

Setting timing involves understanding both initial and total requirements for your combination.

Initial Timing vs Total Timing

Initial timing affects idle quality and starting. Too little causes stalling; too much creates kickback. Total timing matters most for power and detonation resistance. The curve between them optimizes the entire RPM range.

Mechanical timing adjustments (distributor, timing gears)

Loosen the distributor clamp just enough for rotation. Rotate to adjust timing while watching the light, clockwise to retard, counterclockwise to advance on most engines. Fixed-timing engines might use adjustable gears or trigger mounting.

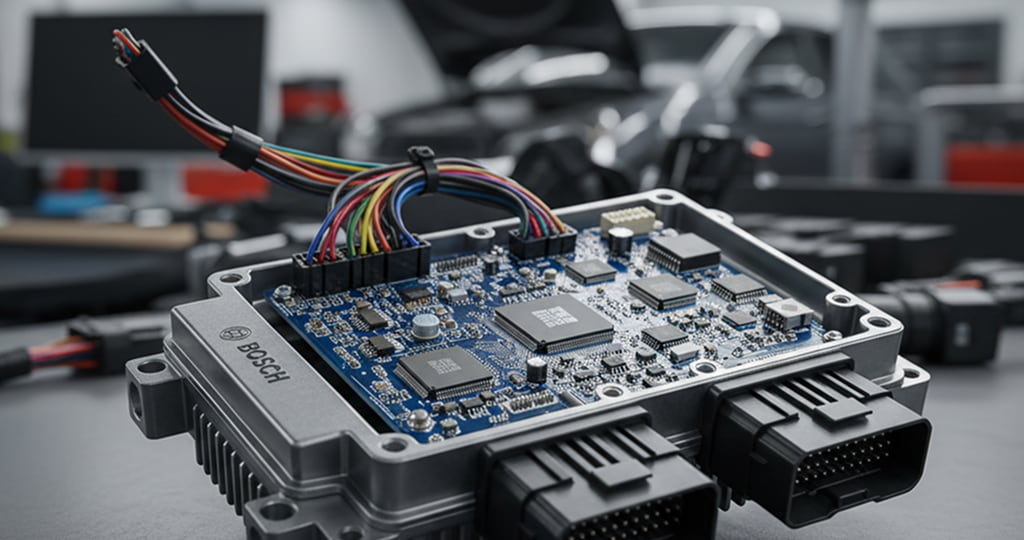

Electronic control via ECU in modern engines

Computer control revolutionized precision. ECUs adjust timing based on sensors including RPM, load, temperature, and knock detection. Aftermarket systems allow complete curve customization.

Step-by-step adjustment procedure

Start with a warm engine at idle. Disconnect vacuum advance. Note current timing. Make small adjustments, 2 degrees at a time. Test total timing by increasing RPM. Reconnect vacuum advance. Road test carefully for detonation. Fine-tune based on actual performance.

Retarding or advancing timing and its effects

Advancing increases power until detonation occurs. Throttle response sharpens, vacuum improves, fuel economy often increases. Too much causes detonation and hard starting. Retarding reduces knock risk but costs efficiency and raises exhaust temperature. Finding balance requires testing your specific combination.

Factors that influence BTDC timing

Optimal timing varies with operating conditions. Four primary factors dominate requirements.

Engine speed (RPM)

Higher RPM needs more advance since combustion time stays constant. Most engines need rapid advance off idle, then gradual increase through midrange. Some combinations benefit from curves that plateau at very high RPM.

Engine load and throttle position

Light cruise tolerates significant advance. Vacuum advance might add 15 to 20 degrees at highway speeds. As load increases, detonation becomes more likely, requiring less advance. Wide-open throttle needs only mechanical advance.

Fuel type and octane rating

Higher octane allows more advance. Race fuel might tolerate 5 to 10 degrees more than pump gas. Low octane requires conservative timing. Ethanol blends burn differently than straight gasoline. E85 often wants slightly more advance.

Compression ratio and engine temperature

Higher compression limits advance. A 12:1 engine might need 6 to 8 degrees less than a 9:1 version. Temperature significantly impacts requirements. Cold engines tolerate more advance. Hot weather might require backing off 2 to 4 degrees.

Symptoms of incorrect BTDC settings

Improper timing reveals itself through various symptoms requiring systematic diagnosis.

Signs of over-advanced timing

Detonation leads the list, that metallic pinging that destroys pistons. Severe detonation cracks pistons and bends rods. Starting problems occur when combustion fights compression. Hot engines resist starting more than cold. That momentary reverse rotation when shutting off indicates too much advance.

Signs of retarded timing

Power loss throughout RPM range accompanies late timing. Acceleration feels lazy. Fuel economy drops as combustion energy exits the exhaust. Heat becomes major issue. Exhaust temperature skyrockets. Headers glow red, exhaust valves overheat. That sweet smell of overheated metal often signals timing needs advancing.

Diagnostic steps for timing issues

Verify basic settings first. Check for balancer slip. Ensure vacuum advance operates smoothly. Road testing reveals dynamic issues. Light throttle surging might indicate vacuum advance problems. Detonation under specific conditions points to advance curve issues. Keep notes on when symptoms occur. Start conservative and advance gradually while testing.

Conclusion

Understanding BTDC transforms timing from mysterious numbers into logical optimization. Those degrees represent the head start combustion needs for maximum efficiency.

Every engine has its sweet spot influenced by compression, cam timing, and fuel quality. Start conservative and advance gradually while monitoring. Real testing beats generic advice every time. When you’re ready to upgrade your ignition system, MotorMia helps you find the right parts for your ride by leveraging AI and her knowledge of hundreds of thousands of builds.