Build Your Dream Ride with Mia

Manual Transmission Tuning

What is manual transmission tuning?

Manual transmission tuning modifies gear ratios, shift points, and clutch engagement to improve performance, fuel efficiency, or driving feel. This process often includes adjusting the ECU, upgrading components like the clutch or flywheel, and refining shift linkages for smoother or faster gear changes.

Think of it as fine-tuning a precision instrument. Stock transmissions work adequately for average drivers, but enthusiasts demand more. Transmission tuning addresses everything from how quickly gears engage to how much abuse your clutch can handle. It’s about making your car work with you, not against you.

The scope ranges from simple fluid changes and shifter adjustments to complete gear ratio swaps and clutch upgrades. Some modifications improve daily driving comfort, others transform your car into a track weapon. The key is matching upgrades to your specific needs rather than throwing parts at problems that don’t exist.

When should you tune a manual transmission?

Knowing when to upgrade your transmission prevents both premature spending and catastrophic failures. Stock transmissions handle stock power levels fine, but several scenarios demand attention to your gearbox.

After engine modifications

Added power exposes transmission weaknesses fast. That stock clutch rated for 200 lb-ft of torque won’t survive long behind your newly turbocharged engine making 350. Even naturally aspirated power gains from cams, headers, and tuning can overwhelm factory components.

Beyond raw power numbers, consider how modifications change power delivery. A big turbo that hits hard at 4,000 RPM shocks the drivetrain differently than linear naturally aspirated power. These shock loads accelerate wear on everything from clutch discs to synchros.

For track or performance driving

Track use multiplies transmission stress exponentially. Heat buildup from repeated hard shifts degrades fluid and wears synchros. The constant high-RPM operation and aggressive driving techniques that make you faster also make stock components fail faster.

Performance driving also reveals gear ratio limitations. Those tall highway gears that save fuel become a liability when you’re trying to keep the engine in its powerband through a series of corners. Track-focused builds often benefit from close-ratio gearsets that trade top speed for keeping you in the sweet spot.

To improve fuel economy or daily drivability

Not all transmission tuning chases lap times. Strategic modifications can transform your daily commute too. A lighter flywheel makes city driving more responsive. Better shifter bushings eliminate slop that makes precise shifts difficult. Even a simple transmission fluid upgrade can smooth out notchy shifting.

Gear ratio changes work both ways. While track cars need shorter gearing, highway cruisers benefit from taller final drives that drop RPM and fuel consumption. The trick is understanding your priorities and building accordingly.

Understanding manual transmission basics

Before modifying anything, understanding how manual transmissions work helps you make smart upgrade decisions. Every component serves a purpose, and changes to one area affect the entire system.

Manual transmissions seem simple because they lack the complexity of automatics, but that simplicity demands precision. Everything from gear engagement to power delivery depends on mechanical components working in perfect harmony. When they don’t, you feel it immediately through the shifter.

Gear ratios and torque multiplication

Gear ratios determine how engine rotation translates to wheel rotation. Lower numerical ratios (like 2.5:1) mean less torque multiplication but higher speeds. Higher ratios (like 4.0:1) multiply torque more but limit top speed in that gear.

Your transmission contains multiple ratio sets working together. Each forward gear has its own ratio, then the final drive ratio affects all gears equally. Changing any ratio shifts your entire powerband up or down the speed range. Understanding this relationship helps you predict how modifications affect real-world performance.

Close-ratio vs. wide-ratio transmissions

Wide-ratio gearboxes space gears far apart, covering a broad speed range with fewer shifts. First gear might be 3.5:1 while second drops to 2.0:1, a massive gap. These work great for street driving where you want first gear for starting from stops and sixth for highway cruising.

Close-ratio transmissions pack gears tighter together. That same first-to-second shift might go from 3.0:1 to 2.5:1. You’ll shift more often, but the engine stays in its powerband better. Race cars use extremely close ratios, sometimes with multiple gear sets for different tracks. Street performance cars balance both needs.

Synchros, clutch engagement, and shift feel

Synchronizers let you shift without grinding by matching gear speeds before engagement. These brass or carbon-lined rings take abuse every shift, wearing slowly over time. When synchros fail, shifting becomes difficult or impossible without rev-matching.

The clutch transfers engine power while allowing disconnection for shifts. Stock clutches use organic friction materials that engage smoothly but can’t handle much extra power. Performance clutches use aggressive materials that grab harder but might chatter during engagement. Finding the right balance matters for street cars.

5 benefits of transmission optimization

1. Improved shift quality and feel

Quality upgrades transform mushy, vague shifts into crisp, mechanical events. Short-throw shifters reduce lever travel. Solid bushings eliminate play. Better fluids reduce notchiness. Combined, these changes make you feel connected to the transmission rather than fighting it.

The psychological benefit matters too. When shifts feel precise and satisfying, you drive better. You’re more likely to heel-toe downshift properly when the transmission rewards good technique. That improved connection makes every drive more engaging, even grocery runs.

2. Faster shift times

Reduced shift times mean less time with the clutch disengaged and more time accelerating. Short shifters physically reduce the distance your hand travels. Lightweight flywheels let RPM drop faster between gears. Better synchros allow quicker engagement without grinding.

Track drivers measure improvements in tenths of seconds per shift. Multiply that by dozens of shifts per lap and hundreds per session, and those tenths become full seconds. Street drivers benefit from safer, quicker gear changes in traffic or during spirited canyon runs.

3. Enhanced power transfer efficiency

Stock transmissions waste power through friction, flex, and heat. Performance upgrades reduce these losses. Better bearings reduce drag. Stronger gear sets flex less under load. Quality fluids maintain viscosity better at temperature. Every improvement means more engine power reaching your wheels.

Efficiency gains appear small individually but compound quickly. A two percent gain here, three percent there, suddenly you’re putting noticeably more power down. Combined with reduced rotating mass from lightweight components, your car accelerates harder without touching the engine.

4. Increased component durability

Upgraded parts last longer than stock when matched to your power level. A clutch rated for your modified engine’s torque won’t slip or burn up. Stronger synchros handle aggressive shifting without wearing prematurely. Better cooling keeps fluid from breaking down.

Durability improvements save money long-term. That expensive twin-disc clutch costs more upfront but lasts years longer than burning through stock clutches every six months. Quality pays for itself through reduced maintenance and fewer failures.

5. Customized driving experience

The best benefit? Making your car truly yours. Want rifle-bolt shifts that reward precise driving? Build for that. Prefer smooth engagement for comfortable daily driving? That’s possible too. Transmission tuning lets you create exactly the driving experience you want.

This customization extends beyond feel to function. Choose gear ratios that match your local roads. Select a clutch that works with your driving style. Build the transmission that makes you smile every time you drive, because that’s the whole point of enthusiast ownership.

5 Main components that can be tuned

1. Clutch system

The clutch bears the brunt of power increases and aggressive driving. Stock organic clutches prioritize smooth engagement and long life at factory power levels. Performance clutches use different friction materials, spring pressures, and designs to handle more torque.

Options range from slightly upgraded organic clutches to multi-plate racing units. Street cars usually run single-disc clutches with various friction materials. Ceramic puck clutches grab hard but chatter. Kevlar blends offer good grip with decent street manners. Full racing multi-plate setups handle huge power but make daily driving miserable.

2. Shifter mechanism

Shifter upgrades directly impact how connected you feel to the transmission. Stock shifters use rubber bushings and long throws for comfort and noise isolation. Performance shifters reduce play and throw length for precise, quick shifts.

Short-throw shifters reduce lever travel by changing pivot points or geometry. Solid bushings replace rubber with aluminum or bronze, eliminating play but increasing noise. Weighted shift knobs add momentum for smoother shifts. Combined properly, these upgrades transform shifting feel without making daily driving uncomfortable.

3. Synchronizers

Synchros rarely get upgraded preventively but become necessary when power or use exceeds stock capacity. Carbon-lined synchros handle more heat and abuse than brass units. Multi-cone designs increase surface area for quicker speed matching.

Upgraded synchros particularly help second and third gears, which see the most use in performance driving. Fourth gear synchros suffer in road racing with constant third-to-fourth shifts. First gear benefits less since you rarely shift into first at speed.

4. Gear ratios

Changing ratios requires transmission disassembly and new gear sets, making this the most involved upgrade. Options include just changing final drive ratio through differential gearing or swapping entire gear sets for different ratios throughout.

Shorter gearing improves acceleration at the cost of top speed and fuel economy. Taller gearing does the opposite. Close-ratio sets keep you in the powerband but require more shifting. The right choice depends entirely on your use case and local driving conditions.

5. Differential Settings

While technically not part of the transmission, the differential works as a system with your gearbox. Open differentials allow speed differences between wheels but can’t put power down with one tire spinning. Limited-slip differentials improve traction by limiting speed differences.

Mechanical LSDs use clutches or gears to limit slip. Helical designs work progressively and quietly. Clutch-type units allow adjustment but wear over time. Welded or spool differentials lock completely but make street driving difficult. Match your differential to your transmission upgrades for best results.

Step-by-step guide to transmission tuning

Step 1: Define your driving goals

Start with an honest assessment of how you actually drive, not how you imagine driving. Track warriors need different setups than canyon carvers or daily commuters. Write down your priorities: Is shift feel more important than clutch longevity? Do you value acceleration over top speed?

Consider your modification timeline too. Planning future engine upgrades? Build the transmission to handle upcoming power, not current levels. This prevents doing the job twice and saves money long-term.

Step 2: Assess current gear ratios

Document your current ratios before changing anything. Check door jambs, glove boxes, or online databases for factory specifications. Calculate RPM at various speeds to understand how ratio changes affect cruising and performance.

Test drive with this knowledge, noting where ratios work and where they don’t. Does fourth gear bog exiting corners? Is first too short for smooth starts? Understanding current limitations guides upgrade decisions.

Step 3: Choose performance parts

Research thoroughly before buying.

MotorMia helps your research journey by turning transmission building from guesswork to science. Our AI-powered platform analyzes thousands of builds to show what works for your specific car and goals.

Budget realistically, including installation costs. A $500 clutch becomes $1,500 after labor. Some upgrades work well together, like combining a lightweight flywheel with clutch replacement since you’re already there. Plan complete systems, not random parts.

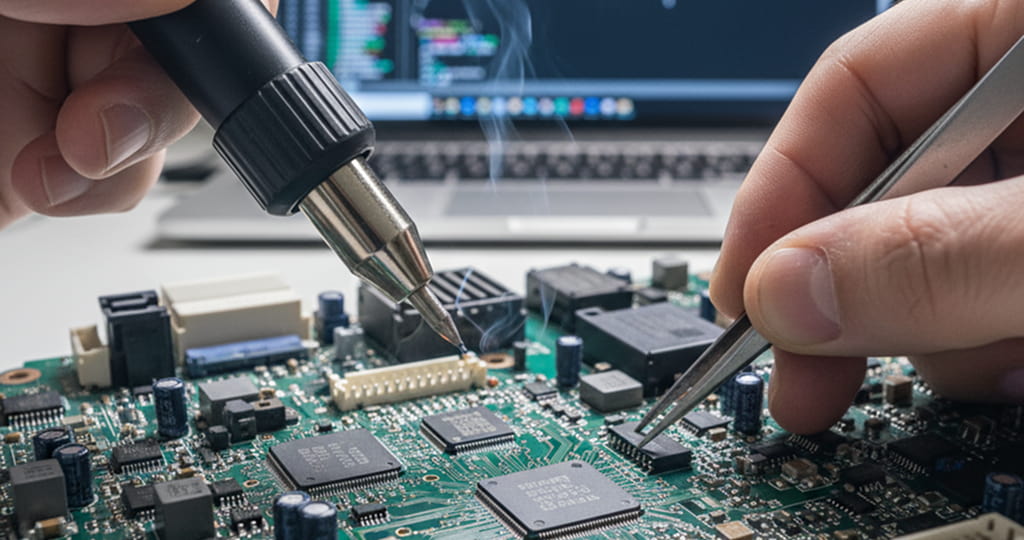

Step 4: Install and adjust components

Professional installation prevents expensive mistakes unless you’re experienced with transmission work. If DIYing, follow factory service procedures exactly. Transmission work requires precision, special tools, and often transmission removal.

Take time with adjustments after installation. Clutch pedal free play, shifter positioning, and linkage adjustment all affect feel. Break in components properly, especially clutches. Those first 500 miles determine long-term performance and life.

Step 5: Road test and reassess

Test systematically in various conditions. Daily driving reveals comfort issues. Spirited driving shows performance gains. Track sessions prove durability. Keep notes about what works and what needs adjustment.

Don’t hesitate to fine-tune after living with modifications. Shifter height, clutch engagement points, and even fluid choices can be adjusted. The goal is a transmission that works perfectly for your needs, not anyone else’s.

Best transmission tuning tools

Quality tools make transmission work safer and more precise. A good jack and stands are non-negotiable for safety. Transmission jacks prevent damage during removal and installation. Proper Allen keys and sockets prevent rounded fasteners.

Specialty tools depend on your transmission. Some need special synchro tools, others require specific seal drivers. Pilot bearing pullers save time and frustration. Clutch alignment tools ensure proper installation. Renting or borrowing expensive specialty tools beats buying for one-time use.

Common Transmission Issues and Solutions

Grinding Gears

Grinding indicates synchros can’t match gear speeds before engagement. Usually starts with one gear, typically second or third. Cold grinding that disappears when warm suggests thick fluid. Consistent grinding means worn synchros.

Solutions range from fluid changes to synchro replacement. Try quality synthetic fluid first, as it’s cheap and often helps. If grinding persists, that synchro needs replacement. Continuing to force shifts accelerates wear and damages gears.

Difficult Shifting

Stiff or notchy shifting has multiple causes. Worn linkage bushings create play and misalignment. Old fluid loses viscosity and lubrication properties. Clutch problems prevent complete disengagement. Cold weather thickens fluid temporarily.

Start with basics: check and adjust linkage, change fluid, verify clutch operation. Solid shifter bushings often solve vagueness. If problems persist, internal issues like worn synchros or bent shift forks need attention.

Clutch Slippage

Slipping clutches can’t transfer full engine power, causing RPM to rise without acceleration. Usually appears under heavy load in higher gears first. Oil contamination, worn friction material, or weak pressure plates cause slipping.

Slipping clutches need immediate replacement before they overheat and damage flywheels. Check for leaks that might contaminate the clutch. Choose replacement clutches rated for your power level with some safety margin.

Gear pop-out

Gears that jump out of engagement indicate worn detents, shift forks, or synchro problems. Usually affects one gear under specific conditions like deceleration. Continued driving risks further damage as gears clash.

Pop-out requires transmission inspection to identify worn components. Worn detent springs allow gears to disengage. Bent shift forks can’t hold gears properly. Excessive shaft play lets gears walk out of engagement. Fix root causes, not symptoms.

FAQ

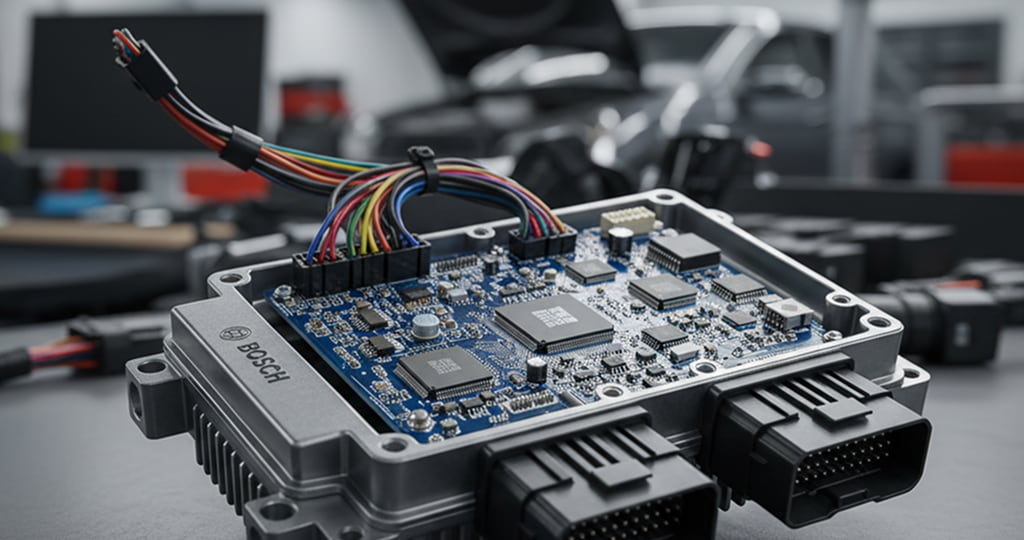

Can you reprogram a manual transmission ECU?

Yes, you can reprogram a manual transmission ECU to adjust shift timing, throttle response, and rev-matching. This tuning optimizes performance and driving characteristics. However, not all manual vehicles have a transmission-specific ECU; some use a shared engine control unit that still allows tuning.

Is tuning a manual transmission worth it?

Tuning a manual transmission is worth it if you seek improved performance, better throttle response, or enhanced driving feel. Upgrades like ECU remaps, short-throw shifters, and lightweight flywheels can deliver noticeable gains. However, the value depends on your driving goals and vehicle compatibility.

Do I need to re-gear for better acceleration?

Yes, re-gearing improves acceleration by changing the final drive ratio, allowing the engine to reach power bands faster. Lower gear ratios increase torque at the wheels, which enhances launch and throttle response. Re-gearing is most beneficial for vehicles with larger tires or performance upgrades.