Build Your Dream Ride with Mia

Engine Modifications: Complete Guide to Power and Performance

What is engine modification?

Engine modification is the process of altering an engine’s components or systems to increase power, efficiency, or performance. Common modifications include installing turbochargers, upgrading fuel systems, reprogramming engine control units (ECUs), and improving cooling systems to handle higher loads or boost levels.

At its core, modifying an engine means improving on what the factory engineers compromised on. From simple bolt-ons that take an afternoon to install to complete rebuilds requiring machine shop expertise, engine modifications range from mild to wild.

The relationship between engine mods and performance

Every modification affects performance differently, and understanding these relationships prevents expensive mistakes. Power gains don’t exist in isolation since improving one area often stresses another. That cold air intake might add 15 horsepower, but now your fuel system needs to keep up. Your new turbo kit doubles power output, but can your cooling system handle the heat?

The modification chain reaction catches many enthusiasts off guard. You start with an exhaust upgrade for better sound and marginal power gains. Then you add an intake because why not maximize airflow? Before you know it, you’re shopping for engine management solutions because the factory ECU can’t optimize for your changes. Each mod builds on the last, creating either a harmonious symphony of power or an expensive collection of mismatched parts.

Performance improvements come in many flavors too. Raw horsepower grabs headlines, but throttle response, power delivery, and reliability matter just as much. A peaky turbo setup might dominate dyno charts but prove frustrating in traffic. Meanwhile, mild naturally aspirated modifications might only add modest power while completely transforming how enjoyable your car becomes.

If you’re looking to plan your modification path strategically, MotorMia’s AI has analyzed thousands of builds similar to yours to recommend proven combinations that deliver the performance characteristics you actually need.

Understanding engine performance basics

Before throwing parts at your engine, understanding the fundamentals saves money and frustration. Modern engines are complex systems where airflow, fuel, spark, and dozens of sensors work together. Change one element without considering the others and you’ll create problems rather than power.

Horsepower vs. torque: What matters most?

The eternal debate misses the point entirely since horsepower and torque tell different parts of the same story. Torque measures rotational force, that shove-you-back feeling when you mash the throttle. Horsepower calculates how quickly that torque gets applied. You need both, but their relationship determines your engine’s character.

High-revving engines make horsepower through RPM, spinning fast to multiply modest torque into big power numbers. These screamers feel sluggish around town but come alive when you wind them out. Torquey engines deliver instant grunt but might run out of breath before redline. Your modification choices shape this balance, so consider how you actually drive, not just peak numbers.

Airflow, fuel delivery, and combustion: The power triangle

Engines are glorified air pumps, and power comes from burning more air and fuel efficiently. Improving airflow means reducing restrictions anywhere between the atmosphere and exhaust tip. But more air demands more fuel, and burning that mixture efficiently requires proper timing and combustion chamber design.

The factory balanced these elements conservatively. Your intake flows enough air for stock power levels with margin for hot days and dirty filters. Fuel injectors deliver precisely metered spray patterns. The ECU manages timing for emissions and reliability across all conditions. Modifications upset this balance, requiring a systematic approach to maintain harmony while increasing output.

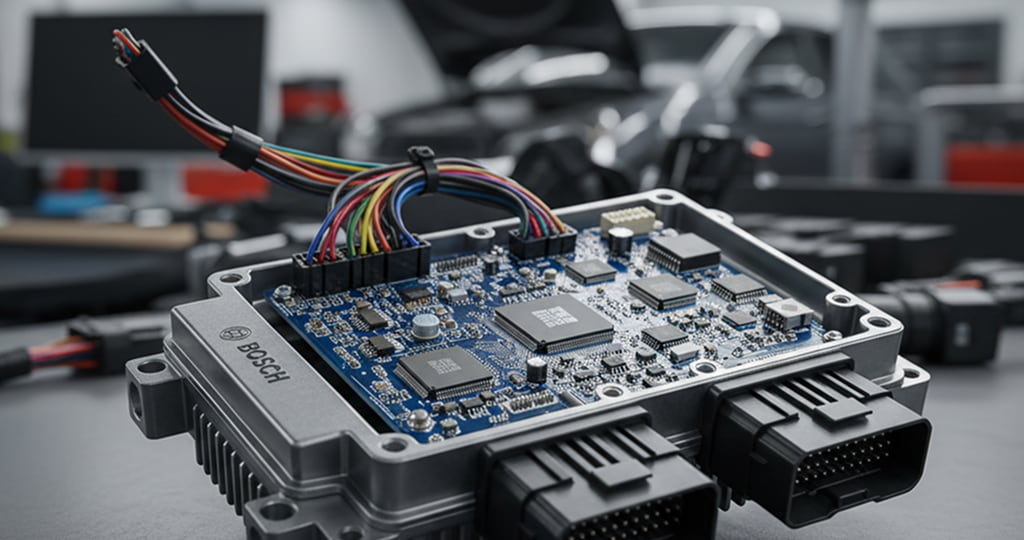

ECU and sensor management in modern engines

Gone are the days of carburetors and distributors you could tune with hand tools. Modern engines rely on electronic control units processing thousands of calculations per second. Mass airflow sensors, oxygen sensors, knock sensors, and cam position sensors feed data streams the ECU uses to optimize performance constantly.

This complexity intimidates some enthusiasts but actually makes modifications more powerful when done correctly. That same ECU limiting your engine for emissions compliance can be reprogrammed to extract significantly more power. The sensor network providing conservative feedback can be calibrated for performance. Understanding these systems transforms them from obstacles into opportunities.

Types of engine modifications

Engine modifications fall into categories based on what they improve and how they integrate with other systems. Starting with bolt-ons and progressing through increasingly complex modifications helps build understanding alongside your engine’s capabilities.

Air intake system upgrades

Intake modifications typically offer the best bang for buck, especially on turbocharged engines. The factory airbox prioritizes quiet operation and long filter life over maximum flow. Aftermarket intakes reduce restrictions, smooth airflow paths, and often relocate the filter to breathe cooler air.

Cold air intakes take this further by ducting air from outside the engine bay. Cooler air is denser, packing more oxygen molecules per volume. Every 10-degree temperature drop can be worth 1-2% more power. Short ram intakes trade some temperature benefit for better throttle response through more direct routing. Both beat the stock setup, just differently.

Exhaust system upgrades

Exhaust modifications serve dual purposes since they reduce backpressure for power gains while completely changing your car’s character through sound. The factory system muffles noise aggressively while meeting emissions requirements through catalytic converters. Performance exhausts balance flow improvements with sound levels you can live with.

Starting at the back, axle-back systems replace just mufflers for sound changes and minimal power gains. Cat-back systems replace everything behind the catalytic converters, offering better flow and more noticeable improvements. Headers or downpipes tackle the most restrictive sections but often require tuning to realize full benefits. Each step gets more expensive and complex but delivers proportionally larger gains.

Forced induction

Nothing adds power like forced induction. Turbochargers use exhaust energy to spin compressors that cram extra air into your engine. Superchargers belt-drive their compressors directly from the crankshaft. Both multiply power potential beyond what naturally aspirated modifications can achieve.

Turbo systems offer efficiency advantages and massive power potential but add complexity through oil lines, intercoolers, and boost control systems. Superchargers provide instant throttle response and simpler installation but consume some engine power to drive themselves. Either route requires extensive supporting modifications and professional tuning for reliability.

Internal engine upgrades

When bolt-ons reach their limits, internal modifications unlock the next level. Forged pistons handle higher cylinder pressures. Upgraded connecting rods resist bending under extreme loads. Performance camshafts alter valve timing for more aggressive profiles. These changes require engine disassembly but enable power levels impossible with stock internals.

The rabbit hole goes deep here. Porting cylinder heads improves flow. Larger valves flow more air. Different compression ratios optimize for specific fuel types. Each modification requires careful integration with others, making internal work best left to experienced builders unless you’re ready for serious education.

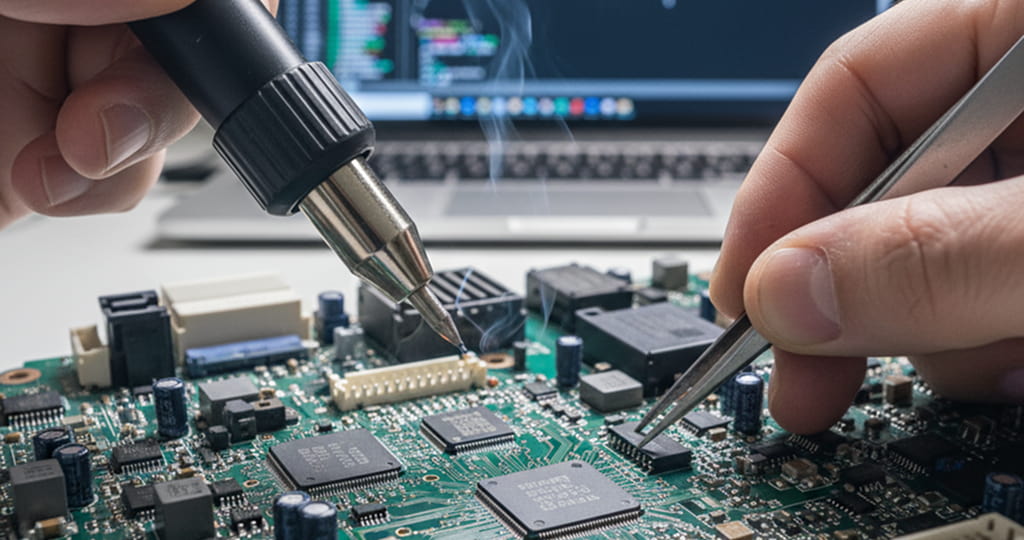

ECU tuning and remapping

Software modifications deliver some of the biggest gains per dollar spent, especially on turbocharged engines. The factory ECU runs conservative maps that leave significant power untapped. Professional tuning optimizes fuel delivery, ignition timing, and boost pressure for your specific modifications.

Off-the-shelf tunes provide decent gains through tested maps for common modifications. Custom dyno tuning goes further by optimizing specifically for your engine’s characteristics. Either beats the factory tune, but custom tuning ensures everything works together optimally while maintaining safe margins.

Fuel system enhancements

More air and aggressive tuning mean nothing without adequate fuel delivery. The factory system supplies enough fuel for stock power plus safety margin. Push beyond that and you risk running lean, which melts pistons faster than anything else.

Upgrades start with higher-flow fuel pumps that maintain pressure under demand. Larger injectors spray more fuel per pulse. Adjustable fuel pressure regulators fine-tune delivery. Flex fuel systems let you run E85 ethanol blends for knock resistance and cooling benefits. Each component must match your power goals without going overboard.

Cooling system upgrades

Heat kills engines, and modifications generate plenty of it. The factory cooling system handles stock power output with reserve for hot days and towing. Add 50% more power and that margin disappears quickly. Cooling upgrades become mandatory for reliability.

Aluminum radiators improve heat dissipation through better core designs and increased capacity. Oil coolers manage temperatures in the lubrication system. Upgraded intercoolers reduce intake air temperatures on forced induction setups. Better cooling doesn’t add power directly but enables you to use what you’ve built without fear.

Engine mounts and reinforcement

Power increases stress throughout your engine bay. Factory engine mounts use soft rubber to isolate vibrations, but they allow excessive movement under hard acceleration. Performance mounts reduce this movement, improving throttle response and shifting feel while preventing stress on other components.

Reinforcement goes beyond mounts. Strut tower braces prevent chassis flex. Subframe connectors stiffen unibody cars. Transmission mounts handle increased torque. These unsexy modifications prevent expensive failures while improving how connected you feel to your machine.

Supporting modifications

Engine modifications don’t exist in isolation. Your transmission needs to handle increased power. Clutches slip when torque exceeds their capacity. Driveshafts twist under brutal launches. Differentials grenading from doubled horsepower make expensive noises.

The supporting cast extends beyond drivetrain components. Suspension upgrades manage weight transfer during acceleration. Better brakes become mandatory when straightline speed increases. Wheels and tires must hook up all that power.

Building a complete package costs more but creates a car that’s actually enjoyable rather than a dyno queen that breaks constantly.

MotorMia helps you identify which supporting mods other builders with your power goals found necessary, potentially saving thousands in broken parts and frustration.

Legal and safety considerations

Performance modifications exist in a grey area between personal freedom and public safety. Emissions laws vary drastically by location, with some areas requiring all factory equipment remain intact while others barely check. Research your local requirements before investing in modifications that might make your car illegal to drive.

Safety extends beyond legality. Doubling your engine’s power without upgrading brakes creates a missile. Stiff engine mounts that improve performance also transmit more noise and vibration into the cabin. Loud exhausts that sound glorious to you might violate noise ordinances and anger neighbors. Balance your enthusiasm with responsibility.

Cost vs. benefit analysis

Smart modifying means understanding diminishing returns. Your first $1,000 in bolt-ons might yield 50 horsepower. The next $1,000 gets you 30. By the time you’re chasing those last few ponies, you’re spending thousands per horsepower. Set realistic goals based on budget and intended use.

Hidden costs multiply quickly too. Installation labor, tuning sessions, supporting modifications, and inevitable repairs add up. That $500 cold air intake becomes $1,200 after professional installation and tune. The $3,000 turbo kit balloons to $8,000 with supporting mods and labor. Budget comprehensively or prepare for sticker shock.

Common mistakes to avoid

Skipping supporting mods

The biggest mistake enthusiasts make involves tunnel vision on power-adding modifications while ignoring everything else. That built engine making 600 horsepower won’t last long with a stock cooling system. Your new turbo kit needs supporting fuel system upgrades or it’ll run lean and melt pistons.

Success requires thinking systematically about how modifications interact. Every power increase stresses other components. Plan complete packages rather than piecemeal upgrades. Yes, this means spending money on “boring” parts like radiators and fuel pumps before the exciting stuff. Your engine will thank you by not exploding.

Over-tuning without proper testing

Aggressive tuning feels great until something breaks. Pushing timing advance for those last few horsepower might seem worth it until detonation cracks a piston. Running boost levels beyond turbo efficiency ranges generates heat without proportional power gains. The temptation to extract every possible horsepower often exceeds mechanical limits.

Conservative tuning with safety margins keeps engines alive. That means leaving some power on the table in exchange for reliability. Professional tuners understand these limits through experience. They know when you’re approaching the edge and pull back accordingly. Trust their judgment over internet claims about what’s possible.

Neglecting reliability for raw power

Big power numbers impress at car meets but mean nothing if your engine won’t last a season. Building for peak dyno numbers often creates peaky, temperamental engines that hate daily driving. That 800-horsepower build might struggle to idle and overheat in traffic.

Consider how you’ll actually use your car. A reliable 400 horsepower you can beat on beats a fragile 600 that requires rebuilds every year. Build in reliability through quality parts, conservative tuning, and proper supporting modifications. Your future self counting repair bills will appreciate the restraint.

Final Thoughts

Engine modification remains one of the most rewarding aspects of automotive enthusiasm. Taking a mass-produced engine and making it yours through carefully chosen upgrades creates connection beyond simple transportation. Each modification teaches something new about how engines work and why engineers made certain choices.

Success comes from education, planning, and realistic expectations. Start small with proven modifications. Learn how each change affects your engine. Build systematically toward clear goals. Accept that mistakes and setbacks are part of the learning process. Most importantly, enjoy the journey as much as the destination because the building never really ends, it just evolves with your skills and goals.

The path from stock to built can take many forms. Some chase numbers, others chase feeling. Both approaches work when executed thoughtfully. Your engine modification journey should reflect your priorities, budget, and intended use. There’s no single right way to build an engine, only the way that makes you grin every time you turn the key.