Build Your Dream Ride with Mia

How To Tune Ignition Timing: Complete Timing Adjustment Guide

Ignition timing might sound like black magic reserved for old-school tuners, but the truth is any enthusiast can learn to dial it in properly.

Modern engines rely on precise spark delivery measured in fractions of a degree. Even small adjustments can mean the difference between an engine that sings and one that self-destructs. The key is knowing when to advance, when to retard, and when to leave well enough alone.

What is ignition timing?

Ignition timing is the precise moment the spark plug fires to ignite the air-fuel mixture in the combustion chamber. Proper timing ensures maximum power and efficiency. Advancing or retarding the spark affects performance, fuel economy, and engine safety under varying RPM and load conditions.

Think of it like throwing a baseball to a moving target. You don’t aim where the target is right now, you aim where it’ll be when the ball arrives. Same principle applies to igniting the air-fuel mixture in your combustion chamber. That flame front needs time to build pressure, so we light the fire while the piston still climbs toward TDC.

Stock timing specs represent a compromise between power, efficiency, emissions, and engine longevity across various conditions. But your specific combination of modifications, fuel quality, and driving style might benefit from custom timing adjustments. The factory had to account for grandma puttering to church and teenagers doing burnouts. Your optimal timing might be very different from what rolled off the assembly line.

How ignition timing works

Ignition timing works by triggering the spark plug to fire at a specific crankshaft angle before the piston reaches top dead center. This ensures the air-fuel mixture ignites at the right moment for peak cylinder pressure. Timing is adjusted based on RPM, load, and engine conditions for optimal performance.

BTDC (Before Top Dead Center) explained

You might also have heard the term BTDC (Before Top Dead Center).

BTDC, or Before Top Dead Center, refers to the crankshaft angle at which the spark plug fires before the piston reaches its highest point in the cylinder. Igniting the air-fuel mixture BTDC allows combustion pressure to peak just after top dead center, maximizing engine power and efficiency.

When should you tune ignition timing?

Tune ignition timing after performance upgrades, to eliminate knock, maximize power, or improve fuel economy. Modifications change combustion needs, requiring timing adjustments. Proper tuning ensures safe, efficient ignition that aligns with your engine’s airflow, load, and fuel quality.

Here is a deeper look at the four most common times to tune your ignition timing.

1. After performance modifications

Any modification that changes how your engine breathes or burns fuel can shift optimal timing requirements. That aggressive cam with increased overlap? It’s probably bleeding off some cylinder pressure at low RPM, requiring more initial advance to compensate. Forced induction setups typically need timing pulled back to prevent detonation under boost.

2. To eliminate engine knock or detonation

That metallic pinging under acceleration isn’t your valves saying hello, it’s detonation trying to ventilate your pistons. When combustion happens too early or too violently, the rapidly expanding gases create shock waves that hammer internal components. Left unchecked, detonation leads to blown head gaskets, cracked pistons, and scattered connecting rods.

3. To maximize power output

Every engine has a sweet spot where timing produces peak power. Too conservative and you leave horsepower in the combustion chamber. Too aggressive and detonation kills power while threatening reliability. Finding that edge requires careful testing and monitoring, but the gains can be substantial.

4. To optimize fuel economy

Proper timing doesn’t just make power, it also improves efficiency. When combustion happens at the optimal moment, more energy converts to crankshaft rotation instead of wasted heat. This means better fuel economy during cruise conditions and daily driving.

What is the best timing toolkit?

The best timing toolkit depends on your engine type, but top-rated universal kits include brands like OTC, OEMTOOLS, and GearWrench. These kits feature camshaft locking tools, crankshaft holders, and timing marks for accurate alignment, ideal for DIY or professional engine timing work.

At minimum, you need an inductive timing light that flashes in sync with your ignition. Better units include digital advance readouts, saving you from squinting at tiny degree marks while things spin at thousands of RPM.

For serious tuning, consider investing in adjustable timing lights with dial-back capability. These let you verify total timing at high RPM without revving the engine to redline in your garage. Add a good tachometer for accurate RPM readings and you’ve got the basics covered.

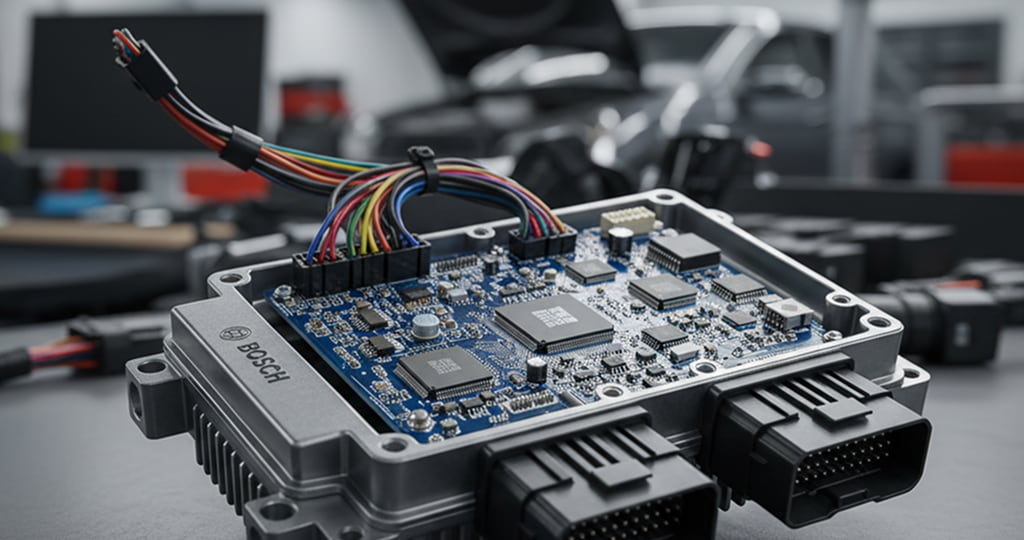

Modern engines often require scan tools or laptop software for timing adjustments since everything happens electronically. OBD-II scanners can display timing values, while tuning software lets you adjust tables directly.

How to check current ignition timing

Before adjusting anything, you need to know where timing currently sits. This baseline measurement reveals whether you’re starting from a conservative factory tune or someone’s previous attempt at optimization.

Using a timing light

Hook your timing light’s inductive pickup around the number one spark plug wire or coil-on-plug connector. The red lead goes to battery positive, black to negative. Start the engine and let it warm to operating temperature. When you pull the trigger, the timing light flashes each time cylinder one fires.

Point the light at your harmonic balancer or flywheel timing marks. The flashing strobe effect makes the spinning marks appear stationary. Line up the reference marks to read current timing. Most engines have a pointer on the block and degree marks on the rotating assembly, though some reverse this arrangement.

Reading ECU data

Modern engines calculate timing electronically, making ECU data more accurate than external measurements. Plug in your scan tool and navigate to live data. Look for “ignition timing” or “spark advance” parameters. This shows real-time timing values as the ECU sees them.

Compare ECU readings to what your timing light shows. Major discrepancies might indicate a jumped timing chain, incorrect base timing, or ECU compensation for other issues. Trust the ECU data for electronic engines, but verify with a timing light when possible.

Identifying timing marks

Every engine places timing marks differently. Some stamp degrees on the harmonic balancer with a pointer on the timing cover. Others cast marks into the flywheel visible through a bellhousing window. Your service manual shows exact locations and which marks indicate TDC versus advance degrees.

Clean those marks before starting. Years of grime make precise reading impossible. A bit of white paint on the appropriate marks helps visibility under strobe lighting. Take time to understand which direction indicates advance versus retard for your specific engine.

Step-by-Step Ignition Timing Adjustment

Timing adjustment requires patience and a methodical approach. Rushing leads to mistakes that cost power or engine damage. Follow these steps whether you’re fine-tuning a distributor or uploading new ignition maps.

Step 1: Warm up the engine

Cold engines need different timing than warm ones. Let your engine reach full operating temperature before making adjustments. This ensures the ECU enters closed-loop operation and represents real-world driving conditions. Oil should be up to temp too, not just coolant.

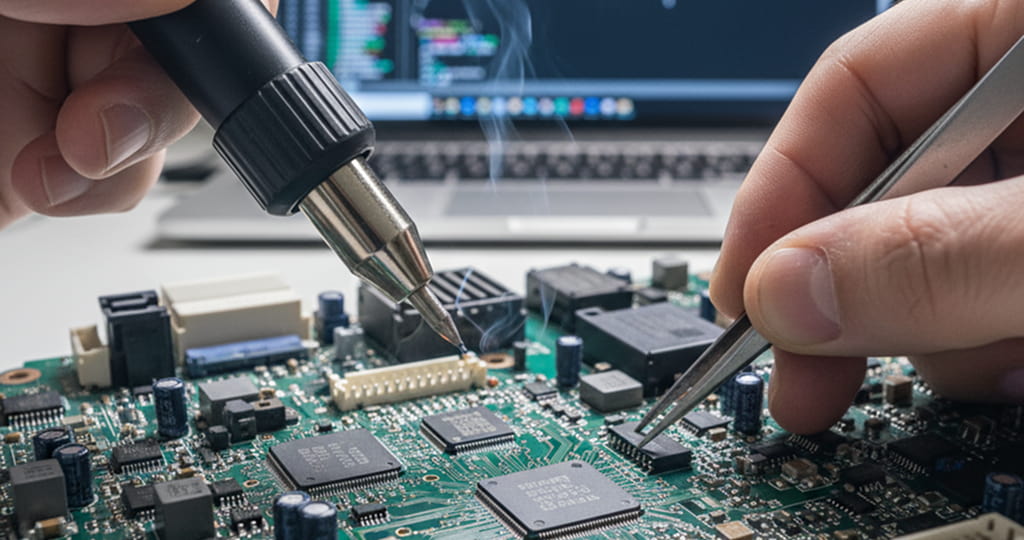

Step 2: Connect diagnostic tools

Hook up your timing light, tachometer, and any scan tools before starting adjustments. Ensure all connections are secure and away from moving parts. If tuning electronically, establish communication with the ECU and save your current tune as a backup.

Step 3: Check base timing

Set the engine to base timing mode by following manufacturer procedures. This might involve disconnecting sensors, jumping diagnostic connectors, or using scan tool functions. Base timing verification ensures the mechanical and electronic systems agree on TDC reference.

Step 4: Adjust timing incrementally

Make small adjustments, typically one or two degrees at a time. For distributors, loosen the hold-down clamp and rotate slightly. Electronic tuning involves changing values in ignition tables. After each change, rev the engine and let it return to idle, checking for smooth operation.

Step 5: Test under load

Static timing only tells part of the story. Real testing happens under load. Whether using a dyno, hill climb, or careful street acceleration, monitor how the engine responds to timing changes through the RPM range. Listen for detonation and watch for power improvements.

Step 6: Monitor for knock

Your ears are the first line of defense against detonation. That metallic pinging or rattling under load means you’ve pushed timing too far. Modern engines might have knock sensors that detect detonation before you hear it. Back timing off immediately if knock occurs.

Step 7: verify and fine-tune

Once you find optimal timing, verify it hasn’t changed after heat cycles and driving. Distributors can shift slightly, requiring readjustment. Electronic tunes should be data-logged to ensure the ECU maintains commanded timing under various conditions.

How can MotorMia help?

Getting timing right often means learning from others who’ve already found the sweet spot for your combination.

Motormia’s AI-powered parts matching also helps you find the right tuning tools and components for your specific engine. Whether you need a quality timing light, ECU tuning software, or supporting mods that work well with aggressive timing, MotorMia’s database cuts through the confusion.

Mia also connects you with verified suppliers offering competitive prices on timing tools and components. Whether you need a professional-grade timing light, ECU tuning interface, or performance ignition components that work with aggressive timing curves, MotorMia’s technology identifies the right parts and shows you where to buy them.

Risks of Improper Ignition Timing

Playing with timing is like juggling fire, get it wrong and things burn down quickly. Understanding the risks helps you respect the process and avoid expensive mistakes.

Engine knock and detonation

Detonation occurs when combustion happens too quickly or in multiple places simultaneously. Instead of a controlled burn, you get explosive shock waves. These pressure spikes can exceed design limits by massive margins, turning internal components into shrapnel.

Piston damage or ring failure

Detonation hammers pistons like a blacksmith’s anvil. Ring lands crack, allowing combustion pressure into the crankcase. Piston crowns can literally melt from excessive heat. Once damage starts, metal particles circulate through your oil system, taking out bearings and scoring cylinder walls.

Decreased engine lifespan

Even without catastrophic failure, improper timing accelerates wear throughout your engine. Too much advance increases stress on everything from head gaskets to main bearings. Too little advance runs temperatures higher, cooking oil and degrading components. The cumulative effect can cut engine life by thousands of miles.

Common Signs of Incorrect Timing

Your engine talks to you through sounds, smells, and seat-of-the-pants feel. Learning to interpret these signals helps catch timing issues before they cause damage.

Pinging or knocking noises

That metallic rattle under acceleration screams “too much advance!” Detonation sounds like marbles in a coffee can or someone knocking on your combustion chamber with a tiny hammer. The noise often appears under load and disappears when you lift off the throttle.

Rough idle or poor acceleration

Incorrect timing disrupts the combustion dance, causing uneven power delivery. Too little advance makes acceleration sluggish, like the engine can’t get out of its own way. Too much advance at idle creates unstable combustion, causing hunting RPM or outright stalling.

Engine overheating

When timing strays too far from optimal, more energy becomes heat instead of power. Retarded timing is especially guilty here, as late combustion continues heating components during the exhaust stroke. Watch coolant temps climb even with a healthy cooling system.

Low fuel efficiency

Bad timing wastes fuel faster than a leaky gas tank. Whether running too conservative or too aggressive, improper combustion means more fuel for less power. If your MPG suddenly drops after timing changes, something needs adjustment.

Advance vs. Retard Timing

| Aspect | Advanced Timing | Retarded Timing |

| Power Output | Generally increases until detonation threshold | Decreases but safer under boost |

| Fuel Economy | Improves with moderate advance | Worsens due to incomplete combustion |

| Engine Temperature | Runs cooler with proper advance | Runs hotter, especially exhaust temps |

| Detonation Risk | Higher risk, especially with poor fuel | Lower risk but less performance |

| Throttle Response | Crisp and immediate | Sluggish and lazy |

| Best Use Case | Naturally aspirated, high-octane fuel | Forced induction, low-octane fuel |

ECU-Based vs Mechanical Timing Adjustment

| Feature | ECU-Based Timing | Mechanical Timing |

| Precision | 0.1-degree increments | 1-2 degree increments typically |

| Ease of Adjustment | Software changes, no tools needed | Requires timing light and wrenches |

| Dynamic Control | Adjusts continuously based on sensors | Fixed curve based on RPM/vacuum |

| Cost | Tuning software and hardware needed | Basic timing light sufficient |

| Complexity | Requires understanding of tables/maps | Simple rotation of distributor |

| Flexibility | Infinite adjustment possibilities | Limited by advance mechanism |

| Reversion | Easy to restore previous settings | Must manually return to original |

FAQ

Can I tune ignition timing without a dyno?

Yes, you can tune ignition timing without a dyno by using road tuning and data logging. Wideband O2 sensors, knock detection, and real-time timing logs help adjust spark advance safely. While a dyno offers precise control, careful tuning on the street can yield reliable results.

Is it safe to advance timing for more power?

Yes, advancing ignition timing can safely increase power if done within limits. It improves combustion efficiency and throttle response. However, excessive advance can cause knock, so use knock sensors and monitor AFR to keep timing within your engine’s safe range.

What happens if timing is too advanced?

If ignition timing is too advanced, combustion occurs too early, causing knock, high cylinder pressures, and potential engine damage. Symptoms include pinging sounds, poor performance, and overheating. Severe cases can damage pistons, bearings, or head gaskets.