Build Your Dream Ride with Mia

Air-Fuel Ratio Tuning: The Complete Guide

What is Air-Fuel Ratio (AFR)?

Air-Fuel Ratio (AFR) is the proportion of air to fuel in an internal combustion engine’s intake mixture. The ideal AFR for gasoline engines is 14.7:1, meaning 14.7 parts air to 1 part fuel. Maintaining proper AFR ensures efficient combustion, performance, and emissions control.

Your engine needs oxygen to burn fuel, and getting the mixture right determines how efficiently that combustion happens. Too much fuel wastes gas and washes oil from cylinder walls. Too little fuel runs hot enough to melt pistons. The sweet spot depends on what you’re asking the engine to do.

Stoichiometric vs rich vs lean

The main difference between stoichiometric, rich, and lean air-fuel mixtures is the ratio of air to fuel. Stoichiometric is the ideal 14.7:1 ratio for gasoline. A rich mixture has more fuel and less air, improving power but reducing efficiency. A lean mixture has more air, improving economy but risking engine damage.

Why AFR matters for performance

AFR matters for performance because it controls combustion quality, power output, and engine reliability. A precise air-fuel ratio ensures optimal burn, delivering maximum horsepower without risking knock or overheating. Incorrect AFR either too rich or too lean can reduce efficiency, cause damage, or limit performance gains.

Power production peaks at specific AFRs that vary with engine design and operating conditions. Most naturally aspirated engines make best power around 12.8:1 to 13.2:1 at wide open throttle.

When and why to tune your AFR

Tune your AFR after installing mods like intakes, exhausts, or forced induction to match fuel with new airflow. Proper AFR tuning improves fuel economy, prevents engine knock, and helps pass emissions by maintaining ideal combustion. It ensures both performance gains and engine reliability across varied driving conditions.

Let’s take a closer look at when and why to tune your AFR.

After installing performance mods

Bolt on an intake, exhaust, or any modification that changes how your engine breathes, and the factory fuel maps no longer match actual airflow. Your ECU tries to compensate using feedback from oxygen sensors, but it can only adjust so far before hitting adaptation limits.

Headers and high-flow cats reduce exhaust backpressure, requiring less fuel for the same power. Cold air intakes increase air density, demanding more fuel to maintain proper ratios. Forced induction multiplies these effects. Every modification shifts the fuel requirements, making proper tuning essential for both performance and reliability.

To improve fuel economy

Running unnecessarily rich during cruise conditions wastes fuel and money. Many factory tunes run slightly rich for safety margins that street driving doesn’t need. Careful leaning of cruise mixtures can improve highway mileage significantly without sacrificing reliability.

The key is identifying where you can safely lean mixtures without risking damage. Light throttle cruise offers the most opportunity, where you might safely run 15:1 or slightly leaner. Just avoid the temptation to chase maximum economy by running dangerously lean ratios that save pennies while risking thousands in repairs.

To prevent engine knock or damage

Detonation destroys engines faster than almost any other failure mode. When your mixture lights off before the spark plug fires, pressure spikes hammer pistons and bearings with forces they weren’t designed to handle. Proper AFR tuning provides the first line of defense against destructive knock.

Rich mixtures help prevent detonation through charge cooling. That extra fuel absorbs heat during vaporization, lowering combustion temperatures. It’s why tuners add fuel under boost or high load conditions. The right AFR gives you a safety buffer without going so rich that you lose power or foul plugs.

To pass emissions tests

Ironically, performance tuning can actually help pass emissions when done right. Catalytic converters work best at stoichiometric ratios, but many modified cars run too rich or lean for cats to function properly. Proper AFR tuning gets you back into the window where emissions equipment works effectively.

The trick is setting up switchable tunes or ensuring your cruise AFRs stay near 14.7:1 when not under load. You keep the performance benefits of optimized WOT fueling while maintaining clean cruise emissions. Just remember that federal law prohibits defeating emissions equipment, so keep those cats in place.

Tools you need to tune AFR

To tune AFR accurately, you need a wideband O2 sensor, an AFR gauge or data logger, ECU tuning software, and dyno access. These tools work together to measure air-fuel ratios, adjust fuel maps, and validate performance under load ensuring safe, optimized combustion for power and efficiency.

Let’s look at the use and role of each tool in AFR tuning.

Wideband O2 sensor

Wideband oxygen sensors are the foundation of accurate AFR tuning. Unlike narrow-band sensors that only indicate rich or lean, widebands provide exact ratio measurements across the entire tuning range. They’ll tell you whether you’re running 11.5:1 or 12.0:1, not just “rich.”

Installation typically involves welding a bung into your exhaust before the catalytic converter. Closer to the engine provides faster response but risks heat damage. Most tuners place sensors 18-24 inches from the turbo or last primary collector. Quality matters here since accurate readings determine whether your tune helps or hurts.

AFR gauge or data logger

Raw sensor data needs display and logging for useful tuning. Standalone AFR gauges provide real-time feedback while driving, letting you spot problem areas immediately. Data loggers go further by recording AFR alongside RPM, throttle position, and other parameters for detailed analysis.

Choose based on your tuning depth. Casual tuners might get by with a simple gauge for monitoring. Serious builds benefit from logging capability that captures transient conditions impossible to watch while driving. Many modern options combine both functions with smartphone connectivity for easy data review.

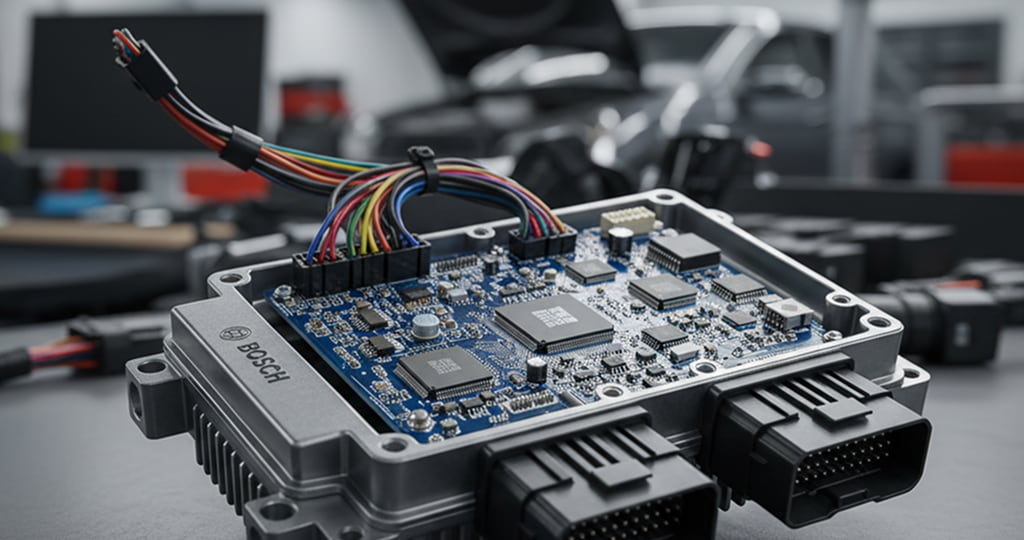

ECU tuning software

Reading AFR is only half the equation since you need the ability to adjust fuel delivery based on what you learn. Open-source options like RomRaider or Hondata let you modify factory ECU maps directly. Standalone engine management systems provide even more control at higher cost.

Start with whatever matches your current ECU and modification level. Flash tuning works great for mild builds while maintaining factory reliability features. Extensive modifications might justify standalone systems that offer advanced features like boost control and flex-fuel capability.

Dyno access

While street tuning is possible, nothing beats the controlled environment and precise load control of a proper dyno. You can hold specific RPM and load points while adjusting fueling, something impossible on the street. Dyno graphs also show power changes from your tuning adjustments.

Expect to pay $100-200 per hour for dyno time, making it expensive but worthwhile for final tuning. Many enthusiasts do initial street tuning to get close, then book dyno time for final optimization.

Step-by-step AFR tuning process

AFR tuning follows a methodical process that builds from data collection through final optimization. Rushing or skipping steps risks missing problems that could damage your engine. Take your time and document everything for future reference.

Here are the six key steps in the AFR tuning process.

Step 1: Connect and configure your tools

Start with proper wideband sensor installation and calibration. Free air calibration ensures accurate readings by exposing the sensor to ambient air while powered. Most quality sensors self-calibrate, but verify yours reads 14.7:1 in free air before trusting any measurements.

Connect your data logging system and verify all parameters read correctly. You want to log AFR, RPM, throttle position, manifold pressure, and coolant temperature at minimum. Set appropriate sampling rates since too slow misses important transitions while too fast creates unwieldy files.

Step 2: Record current AFR values

Drive through various conditions while logging before making any changes. Include cold start, warm idle, light cruise, acceleration, and wide open throttle pulls. This baseline data shows where your current tune needs work and provides a reference for improvements.

Pay special attention to transition areas where the ECU switches between fuel maps. You might find lean spots during tip-in or rich conditions during overrun. Street logging should cover the conditions you actually drive in, not just wide open throttle heroics.

Step 3: Identify problem areas

Review your logs looking for AFRs outside target ranges for each condition. Spreadsheet software helps visualize data and spot trends. Look for consistent patterns rather than isolated spikes that might be sensor noise or unusual conditions.

Common problem areas include lean cruise from conservative factory tunes, rich idle from oversized injectors, and lean spots during boost transitions. Create a list of specific RPM and load points needing adjustment before touching any fuel maps.

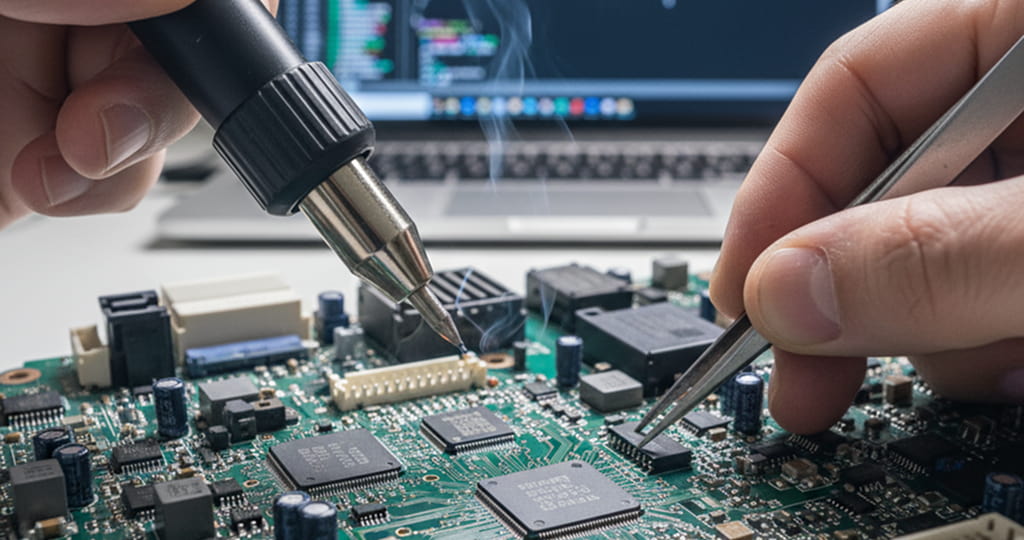

Step 4: Adjust fuel maps

Make small fuel adjustments to problem areas identified in your logs. Start with 3-5% changes rather than massive swings that could overcorrect. Focus on one operating region at a time, such as idle or cruise, before moving to others.

Save your original tune before making changes, and create new versions for each tuning session. This lets you revert if adjustments make things worse. Document what you changed and why for future reference.

Step 5: Test and verify changes

After each adjustment session, log the same driving conditions to verify improvements. Your AFRs should move closer to targets without creating new problems elsewhere. Watch for unexpected changes in areas you didn’t adjust, which might indicate table overlaps or correction factors.

Repeat the adjust-test cycle until AFRs fall within acceptable ranges across all conditions. This iterative process takes patience but ensures thorough optimization without overshooting targets.

Step 6: Fine-tune under load

Once street tuning gets you close, dyno time allows precise load-based adjustments impossible on public roads. Hold specific RPM and load points while fine-tuning fuel delivery for maximum power without sacrificing safety margins.

Focus on wide open throttle optimization during dyno sessions since that’s hardest to tune on the street. Make small adjustments between pulls, watching how AFR changes affect power output. The goal is finding the edge of the best power without running dangerously lean.

Ideal Air-Fuel Ratios for different conditions

Target AFRs vary dramatically based on what you’re asking the engine to do. Understanding these targets prevents chasing wrong numbers that hurt either performance or reliability.

Ideal AFRs vary by condition: cruise at 15–16:1 for economy, target 12.5–13:1 at wide open throttle for power, run rich around 12:1 at cold start for smooth ignition, and lean out near 14.7:1 during idle or deceleration for stability and emissions control.

Let’s look at the most conditions and the ideal AFR for each.

Cruising and economy

Light throttle cruise offers the best opportunity for lean operation. Target 14.7:1 to 15.2:1 during steady-state highway driving. Some engines tolerate 15.5:1 or leaner, but diminishing returns and increased risk make extreme lean cruise questionable.

City driving and moderate acceleration need richer mixtures around 14.0:1 to 14.5:1. The frequent throttle changes and varied loads make ultra-lean operation unstable. Focus cruise tuning on highway conditions where you spend most time.

Wide Open Throttle (WOT)

Maximum power typically occurs between 12.5:1 and 13.2:1 for naturally aspirated engines. Start at 12.8:1 and adjust based on dyno results and engine characteristics. High compression engines might prefer slightly richer while mild builds can run leaner.

Forced induction changes everything. Turbocharged engines often run 11.5:1 or richer under boost for safety. The extra fuel provides charge cooling and detonation resistance crucial for boosted applications. Some tuners run even richer at high boost levels.

Cold start and warm-up

Cold engines need extra fuel to compensate for poor fuel vaporization. Expect AFRs around 12:1 or richer during initial cold start, gradually leaning as coolant temperature rises. This enrichment is why you smell fuel on cold mornings.

Warm-up enrichment should taper smoothly to normal operating ratios within a few minutes. Extended rich operation wastes fuel and increases cylinder wear. Modern engines with proper tuning reach operating temperature quickly without excessive enrichment.

Deceleration and idle

Idle AFR typically targets stoichiometric or slightly rich around 14.2:1 to 14.5:1. Rich idle helps stability with aggressive cams or large injectors. Too rich fouls plugs while too lean causes unstable idle and stalling.

Deceleration fuel cut improves economy and reduces emissions during coast-down. Many tunes shut off fuel entirely above certain RPM with closed throttle. This explains the popping and burbling from some exhaust systems during deceleration.

Target AFRs for gasoline engines

| Condition | Target AFR |

| Idle/Cruise | 14.7-15.0:1 |

| Light Acceleration | 14.0-14.5:1 |

| WOT (Naturally Aspirated) | 12.5-13.2:1 |

| WOT (Forced Induction) | 11.0-12.0:1 |

| Cold Start | 11.5-13.0:1 |

| Deceleration | 15.0:1 or fuel cut |

FAQ

What are the risks of running a too lean or too rich mixture when tuning

Running too lean increases combustion temperature, risking engine knock, overheating, or piston damage. Running too rich can foul spark plugs, reduce power, and waste fuel. Both conditions harm performance and longevity, making proper air-fuel ratio tuning critical.

How can I use a wideband sensor to precisely tune my air-fuel ratio

Use a wideband sensor to monitor your air-fuel ratio in real time across the engine’s operating range. It provides accurate AFR data, helping you adjust fuel maps during tuning to avoid lean or rich conditions. Connect it to your ECU or tuning software for live feedback and fine adjustments.

Why is achieving an AFR of 14.7:1 important for engine efficiency and emissions

An AFR of 14.7:1 is ideal for gasoline engines because it enables complete combustion, maximizing fuel efficiency and minimizing harmful emissions. This stoichiometric ratio ensures the catalytic converter operates effectively, meeting emission standards while maintaining performance.