Build Your Dream Ride with Mia

Complete Guide to Engine and Power Upgrades

Why upgrade your engine?

That factory engine under your hood? It’s a compromise. Engineers designed it to meet emissions standards, achieve fuel economy targets, and last 200,000 miles with minimal maintenance. Performance came fourth or fifth on their priority list. But you didn’t buy your car to be average, and neither did the thousands of enthusiasts squeezing every last horsepower from their builds.

Engine upgrades transform your driving experience in ways suspension and cosmetic mods simply can’t match.

Newer engines enhance acceleration, reduce emissions, and support advanced technologies. Engine upgrades are especially important for aging vehicles or when modifying performance for towing, racing, or off-road use.

Whether you’re chasing quarter-mile times, carving canyons, or just want to embarrass that guy in the BMW at the stoplight, more power opens possibilities. The question isn’t whether to upgrade, it’s how far down the rabbit hole you’re willing to go.

The role of engine mods in performance tuning

The role of engine mods in performance tuning involves improving various aspects of the engine to enhance power, torque, and efficiency. These modifications often include changes to the intake, exhaust, ECU, and internal components.

Modern engines leave surprising headroom for improvement. Manufacturers tune conservatively for warranty concerns and broad market appeal. This means your “sport” model probably has another 20-30% power hiding inside, waiting for the right modifications to unlock it. Even naturally aspirated engines respond well to breathing mods and proper tuning.

Performance vs reliability: striking the right balance

Here’s the truth veterans learn the hard way: doubling your horsepower usually quarters your reliability. Every modification shifts the balance between performance and longevity. Smart builders understand this trade-off and plan accordingly.

The key lies in building for your actual usage, not YouTube fame. A 600-horsepower daily driver sounds awesome until you’re stranded roadside for the third time this month. Meanwhile, that “boring” 300-horsepower setup runs flawlessly year after year while still providing plenty of smiles per gallon.

Types of engine upgrades

Types of engine upgrades include turbochargers, superchargers, ECU remapping, cold air intakes, performance exhausts, and internal component replacements like pistons and camshafts. Each upgrade targets specific performance gains such as increased horsepower, torque, fuel efficiency, or engine response.

Understanding each category helps you plan a build that matches your goals, budget, and mechanical confidence.

MotorMia’s AI can analyze your build and show you proven upgrade paths, taking the guesswork out of compatibility and performance gains.

Naturally aspirated performance enhancements

NA builds prove you don’t need forced induction for serious performance. Intake and exhaust upgrades form the foundation. Cold air intakes, larger throttle bodies, and ported manifolds help engines breathe easier. Headers and cat-back exhausts reduce restriction. Combined with proper tuning, these mods can net 15-25% gains.

Going deeper requires opening the engine. Performance camshafts change valve timing for more aggressive profiles. Higher compression pistons squeeze more power from each combustion. Lightweight valvetrain components allow higher RPM operation.

Forced induction systems (turbochargers vs superchargers)

Nothing adds power like forced induction. Turbochargers use exhaust gases to spin a turbine that compresses intake air. This “free” power comes with some lag as turbos spool, though modern designs minimize delay. Turbos excel at making huge peak numbers.

Superchargers belt-drive their compression directly from the crankshaft, delivering instant power throughout the RPM range. No lag, just linear acceleration. The trade-off comes in parasitic loss since the engine must drive the supercharger.

Engine swaps and crate engines

Sometimes the best upgrade means starting fresh. Popular swaps follow proven recipes. LS engines find homes in everything from Miatas to 240SXs. K-series Honda motors breathe new life into older Civics.

Crate engines simplify the process. These brand-new powerplants arrive ready to install with known specifications. While more expensive than junkyard motors, crates eliminate unknowns that make swaps challenging.

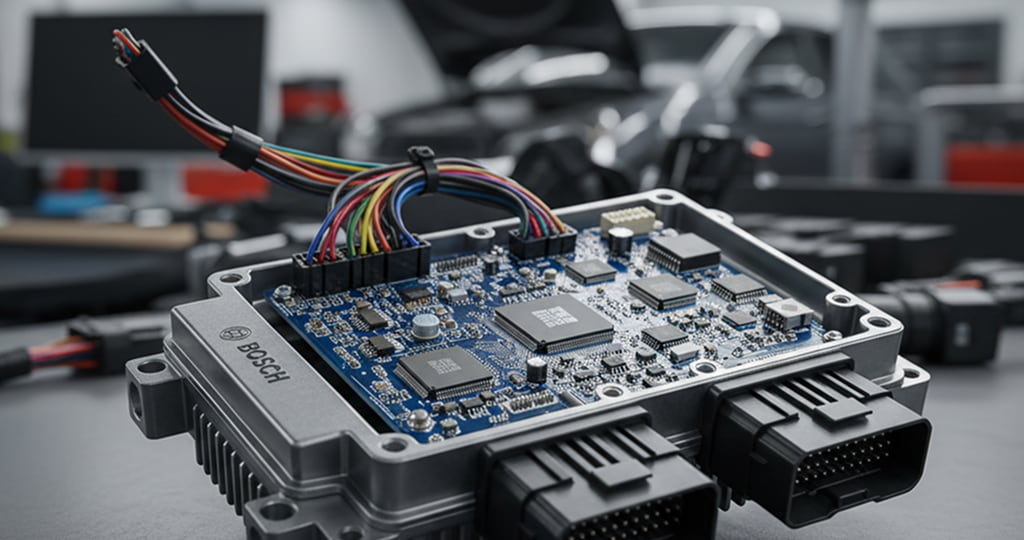

ECU tuning and remapping

Every modern engine runs on computers programmed for the lowest common denominator. ECU tuning unleashes performance by optimizing fuel maps, ignition timing, and boost levels for your specific modifications.

Reflashing the factory ECU rewrites its programming to support modifications. Standalone engine management systems replace the factory ECU entirely, offering infinite adjustability for serious builds.

Internal engine modifications (cams, pistons, rods)

Building power beyond bolt-on levels requires strengthening the rotating assembly. Forged pistons and connecting rods handle increased cylinder pressures. Upgraded bearings and crankshafts support additional loads.

Cylinder head work unlocks serious NA power. Porting, larger valves, and performance camshafts optimize airflow. These modifications require precision machine work but deliver lasting results.

Cooling system upgrades

More power means more heat. Upgraded radiators shed heat more effectively. High-flow water pumps ensure proper circulation. Oil coolers become mandatory for track use.

Intercoolers for forced induction cars reduce intake temperatures for denser air charges. Front-mount conversions might require bumper cutting but prevent heat soak during hard driving.

Exhaust and intake system improvements

Breathing modifications offer the best bang for buck. Intake upgrades deliver cool, dense air with minimal restriction. Proper heat shielding matters as much as pipe diameter.

Exhaust modifications start at the engine. Long-tube headers replace restrictive manifolds. High-flow cats reduce back pressure. Just remember that too large kills velocity and hurts low-end torque.

Power-boosting supporting mods

Engine upgrades don’t exist in isolation. Supporting modifications ensure your newfound power reaches the ground reliably. MotorMia’s build planner helps you identify which supporting mods your power level demands.

Upgraded fuel delivery systems (injectors, pumps, rails)

Stock fuel systems support stock power, period. Larger injectors flow more fuel to match increased air. Sizing matters since oversized injectors hurt idle quality.

High-flow fuel pumps ensure adequate pressure throughout the system. Fuel rails and regulators complete the upgrade for consistent delivery under all conditions.

Transmission enhancements (clutch, flywheel, gearbox)

Performance clutches use aggressive materials to handle added torque. Single-disc setups work for moderate builds while multi-disc clutches support extreme power.

Transmission internals need attention too. Upgraded synchros and stronger gear sets handle additional stress. Don’t forget transmission cooling for sustained use.

Ignition system tuning

High-energy ignition coils deliver reliable spark under tough conditions. Proper plug heat range prevents pre-ignition. Ignition timing through tuning makes or breaks performance.

Lightweight pulleys and rotating assemblies

Reducing rotating mass pays dividends. Underdrive pulleys reduce parasitic drag. Lightweight internal components allow higher RPM and quicker response.

Measuring power gains

Numbers tell stories when measured correctly. Understanding what dyno numbers mean separates real builders from bench racers.

Horsepower vs torque explained

Torque measures rotational force while horsepower calculates how quickly that force works. You feel torque, you see horsepower. Peak numbers tell part of the story, but area under the curve matters more.

Using a dyno to validate upgrades

Chassis dynos measure wheel power while engine dynos test at the crank. Proper testing requires controlled conditions. Multiple pulls ensure consistency and reveal potential issues.

Understanding drivetrain loss

Power never fully reaches the ground. Manual transmissions typically lose 15% while automatics approach 20%. All-wheel drive adds another penalty. Factor losses into expectations.

Cost and complexity of engine upgrades

Money talks in engine building, usually saying “you need more of me.” Understanding cost structures helps plan builds that achieve goals without requiring second mortgages.

Complexity scales with ambition, so honest assessment of skills and resources prevents half-finished projects.

Entry-level bolt-ons vs. full builds

Bolt-ons offer immediate gratification. Intake, exhaust, and tune might cost $2,000 total. Mid-level forced induction jumps to five figures. Full builds start around $20,000 and climb rapidly.

Budgeting for labor, parts, and tuning

Parts costs represent only part of the equation. Professional installation often matches or exceeds parts prices for complex modifications. That $3,000 turbo kit might require $3,000-5,000 in labor for proper installation, fabrication, and integration.

Tuning costs catch many builders off guard. Proper calibration requires dyno time, road testing, and expertise that commands premium rates. Budget $1,000-3,000 for quality tuning on significant builds. Skimping here wastes every dollar spent on parts.

Hidden costs multiply quickly. Gaskets, fluids, fasteners, and miscellaneous parts add 20-30% to initial estimates. Tools for specialty jobs either require purchase or shop time. Failed parts during break-in happen more often than anyone admits. Budget accordingly or face difficult decisions mid-build.

Timeframe and stages of upgrades

Rome wasn’t built overnight and neither are proper engine builds. Staged approaches spread costs while allowing evaluation between phases. Start with breathing mods and tuning to establish baselines before adding forced induction or internal work.

Phase one typically includes intake, exhaust, and engine management upgrades. This foundation supports future modifications while delivering immediate improvements. Phase two might add forced induction or aggressive NA modifications. Phase three goes inside the engine for serious power levels.

Timeline reality checks prevent frustration. Simple bolt-ons take weekends while engine builds consume months. Parts availability, fabrication requirements, and tuning schedules stretch timelines further. Professional shops juggle multiple projects, adding weeks to estimates. Plan for delays because they always happen.

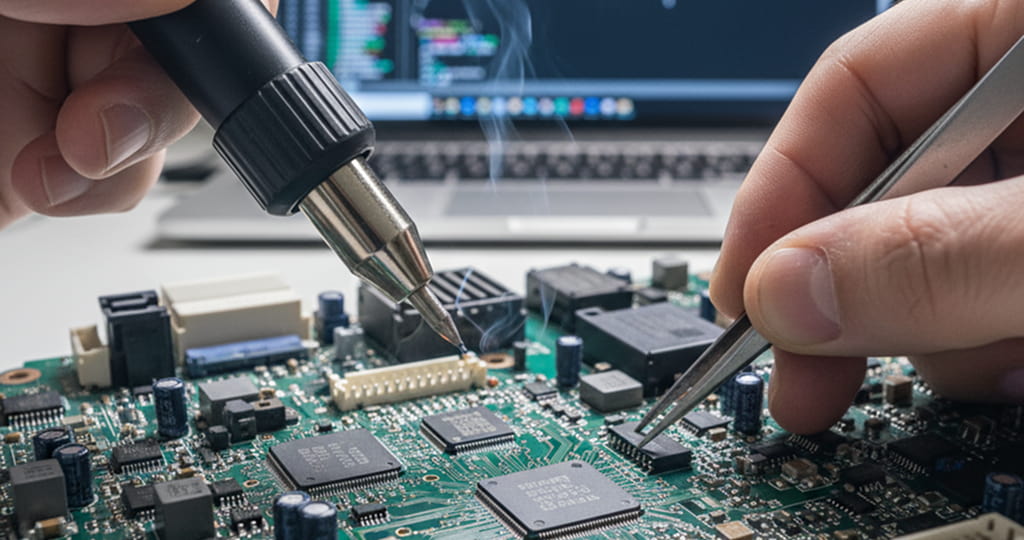

Tuning after upgrades

Tuning transforms expensive parts into actual performance. Without proper calibration, modifications often hurt more than help. This critical step separates successful builds from expensive failures.

Why proper tuning is critical

Modern engines rely on precise fuel and timing strategies for performance and survival. Change anything significant and those strategies no longer work correctly. Proper tuning recalibrates everything for your specific combination of modifications.

Running too rich wastes fuel and washes down cylinder walls. Too lean melts pistons in seconds. Incorrect timing causes detonation that destroys engines. Boost control issues lead to catastrophic failures. Only proper tuning prevents these expensive mistakes.

Beyond safety, tuning extracts maximum performance from modifications. That expensive turbo kit might only deliver 60% of its potential without optimization. Professional tuners understand how to balance power, reliability, and drivability for your specific goals.

Dyno tuning vs road tuning

Dyno tuning offers controlled conditions for precise calibration. Load-bearing dynos simulate real driving while monitoring every parameter. Tuners can safely explore limits without risking traffic incidents. The consistency allows methodical optimization across the entire operating range.

Road tuning uses real-world conditions for final calibration. Hills, temperature variations, and altitude changes test calibrations in ways dynos can’t replicate. Quality tuners combine both methods, using dynos for base maps and roads for refinement.

Data logging during road testing reveals issues dynos might miss. Part-throttle response, transient conditions, and cold-start behavior show up in daily driving. Professional tuners spend hours analyzing logs to perfect every aspect of operation.

Engine management systems and piggybacks

Choosing engine management depends on modification extent and goals. Piggyback systems intercept and modify factory signals for basic adjustments. These work well for mild modifications but lack capabilities for serious builds.

Reflashing or replacing factory ECUs provides more control. Modern tools allow extensive modification of factory strategies while maintaining integration with vehicle systems. This approach balances capability with convenience for street cars.

Standalone systems offer unlimited control for race applications. Every parameter becomes adjustable with resolution factory systems can’t match. The complexity requires professional installation and tuning but enables builds impossible with factory management.

Legal and insurance considerations

Performance modifications exist in complex legal landscapes. Understanding regulations prevents expensive problems.

Emissions compliance and regulations

Federal laws restrict modifications affecting pollution controls. CARB regulations set standards many states adopt. Working within regulations doesn’t mean sacrificing performance.

Insurance implications for engine swaps and upgrades

Standard policies don’t cover modifications without endorsements. Engine swaps complicate coverage further. Performance modifications affect premiums significantly.

Common mistakes to avoid

Every experienced builder has horror stories about lessons learned the expensive way. Smart enthusiasts learn from others’ mistakes rather than repeating them. These common errors destroy more builds than any other factors.

Skipping supporting upgrades

Focusing solely on power-adding modifications while ignoring supporting systems guarantees problems. That big turbo needs fuel system upgrades to prevent lean conditions. Doubled horsepower requires transmission improvements to handle the torque.

Cooling systems top the overlooked list. Stock radiators can’t handle doubled heat output from modified engines. Oil coolers become mandatory for track use. Upgraded intercoolers prevent heat soak that kills power and risks detonation.

Braking systems need attention too. More power means higher speeds requiring better stopping capability. Suspension components stressed by increased acceleration forces wear prematurely. Budget for complete system upgrades rather than just headline modifications.

Overpowering stock internals

Stock internal components have finite strength limits. Push beyond those limits and catastrophic failures follow. That connecting rod rated for 400 horsepower won’t survive 600 no matter how good your tuning.

The temptation to “see what it’ll take” destroys engines regularly. Stock pistons crack, rods bend, and crankshafts break when overstressed. Building proper foundations before adding power costs more initially but prevents rebuilding engines repeatedly.

Research your engine’s weak points before modifications. Some engines handle double stock power while others fail with mild upgrades. Online communities document failure points for every popular platform. Use this knowledge to plan builds that last.

Ignoring fuel and cooling requirements

Fuel starvation and overheating end more performance driving sessions than any other issues. Stock fuel pumps can’t supply enough volume for serious power. Factory cooling systems overwhelm quickly during sustained high-load operation.

Fuel system upgrades scale with power requirements. Pumps, injectors, lines, and rails all need consideration. Running out of fuel delivery headroom leads to lean conditions that melt engines in seconds. Build fuel systems with 20% overhead for safety.

Cooling requires systematic approaches. Larger radiators help but need proper airflow for effectiveness. Ducting, fans, and shrouding complete the system. Oil and transmission cooling prevents secondary failures that sideline builds. Address every heat source for reliable operation.

Final thoughts: Building for longevity and fun

Engine building rewards patience and planning with incredible driving experiences. Whether chasing numbers or smiles, success comes from matching builds to realistic goals. The journey teaches valuable lessons while creating machines that deliver thrills impossible in stock form.

Start with clear objectives based on actual use patterns. Build quality foundations before chasing peak power. Invest in proper tuning and supporting modifications. Most importantly, enjoy the process because the build journey matters as much as the destination.

Your perfect build exists somewhere between stock limitations and race car extremes. Finding that balance requires honest assessment of skills, budget, and intended use. With proper planning and quality execution, you’ll create something that delivers satisfaction every time you turn the key.

And when you need help finding the right parts for your build, MotorMia’s comprehensive database and AI-powered recommendations can guide you toward components proven to work on your vehicle.